MATRIX-I FT-NIR Spectrometer Bruker

MATRIX-I FT-NIR Analyzer

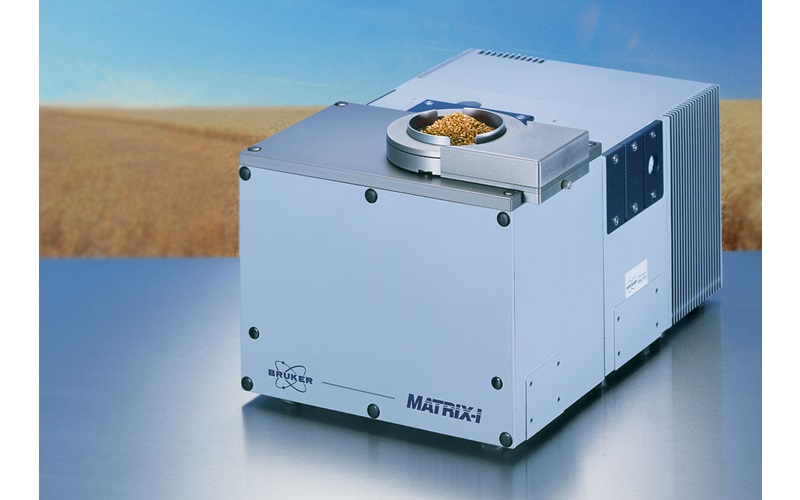

Robust at-line FT-NIR Spectrometer

Bruker's MATRIX-I offers a unique solution for your QA/QC needs utilizing FT-NIR technology.

The MATRIX-I is a rugged FT-NIR spectrometer designed for QA/QC analysis. The system is based on the R&D 100 award winning MATRIX-F spectrometer. The instrument comes equipped with an integrating sphere. This permits fast and easy analysis using the diffuse reflectance technique. Samples can be measured directly in their containers or poured into standard cups. This method is ideal for measuring large amounts of materials and is particularly useful for analyzing inhomogeneous samples or large particle size items such as grains or seeds.

Rugged and compact system

MATRIX-I’s permanently aligned optics and insensitivity to vibrations and temperature changes, make it a perfect rugged and compact system for laboratory and at-line analysis. Secure computer interfacing via standard ethernet, using TCP/IP protocol and an embedded HTML server, enables fast and reliable connectivity.

Easy maintenance

Fourier Transform technology allows higher resolution, better sensitivity, higher wavelength accuracy and easy calibration transfer from one instrument to another. Maintenance of the system is simple, since all consumable components (such as the laser and sources) are on pre-aligned mounts for quick exchange.

Applications for your quality control

The MATRIX-I with its integrating sphere sampling is ideal for your daily QA/QC work. Applications include:

- Grain and oil seed analysis: moisture, protein, oil, starch and fatty acid profile.

- Milk and dairy analysis: moisture, fat, protein and dry matter.

- Food and feed analysis: protein, starch, fat, moisture, fiber and ash.

- Fuel ethanol analysis: fermentation profiling.

- Tobacco analysis: leaf quality and process verifications of tobacco blends.

- Pharmaceutical analysis: raw material ID, blend uniformity, blend ratio, drying process monitoring.

- Polymer lab and online analysis: additives, melt flow index, residual monomer, density and viscosity.